Case Study: 3D Printing a Full-Size PC Model in 32 Hours

One of our customers put the “rapid prototyping” aspect of 3D printing to the test by asking us to produce a full-size model of a computer case in less than 36 hours.

Problem

Scott discovered on a Tuesday evening that he needed to bring a full-size prototype of a computer case design to a customer demo that Friday. With only a couple of days of notice, Scott needed a quick way to produce a display-quality prototype to show to his customer. He needed to get moving on the project quickly.

This PC model would take over 50 hours to print in one piece, but we only had 32 hours to complete the project

Fortunately, we’re available nearly 24/7 and were available to discuss the project with him at 10PM when he contacted us. Despite the late hour, we were able to get started on the 3D printing immediately. However, the deadline was going to be a challenge--even with overnight shipping, we would need to get all of the printing done by Thursday morning to get the prototype to Scott on time.

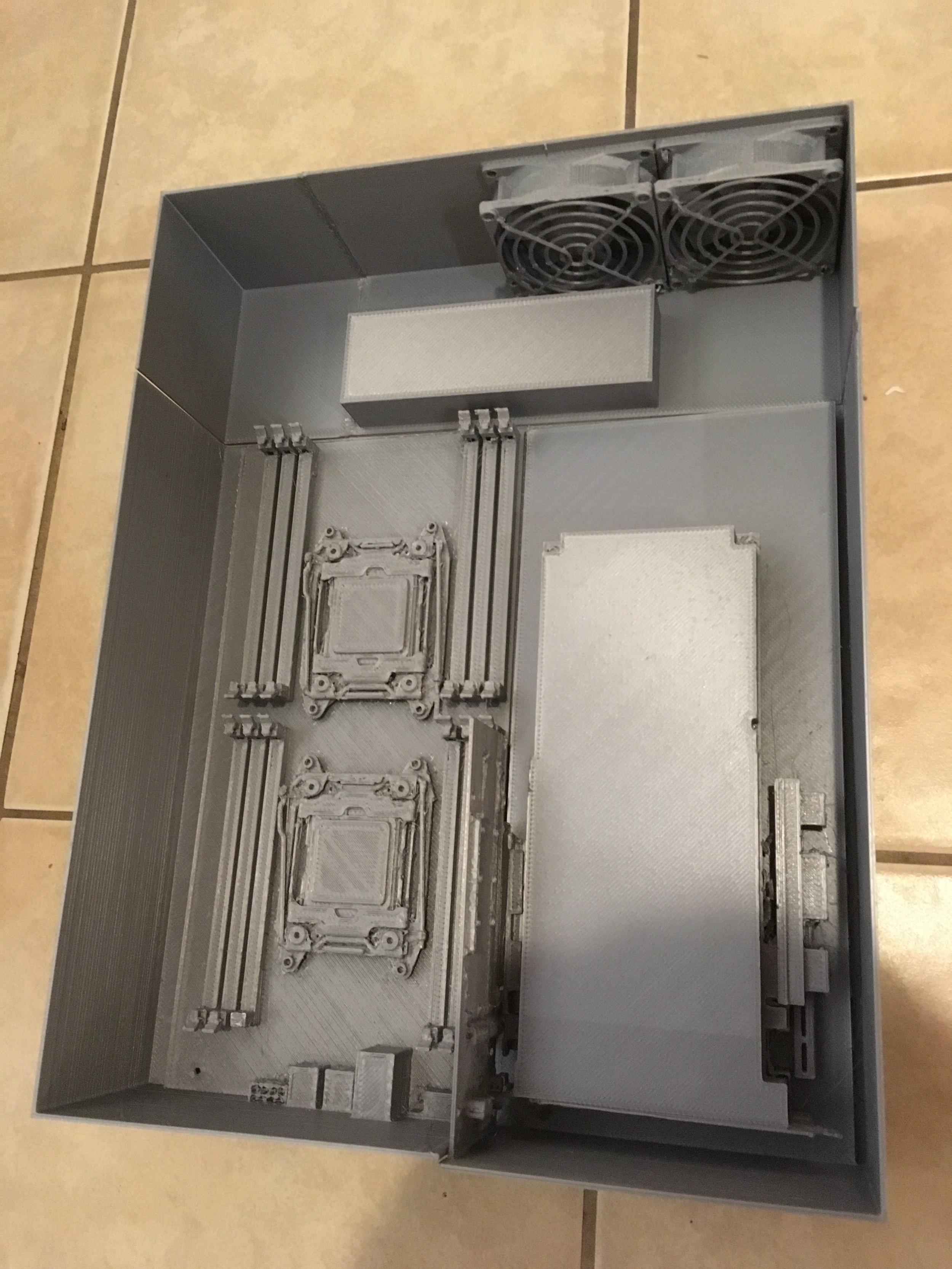

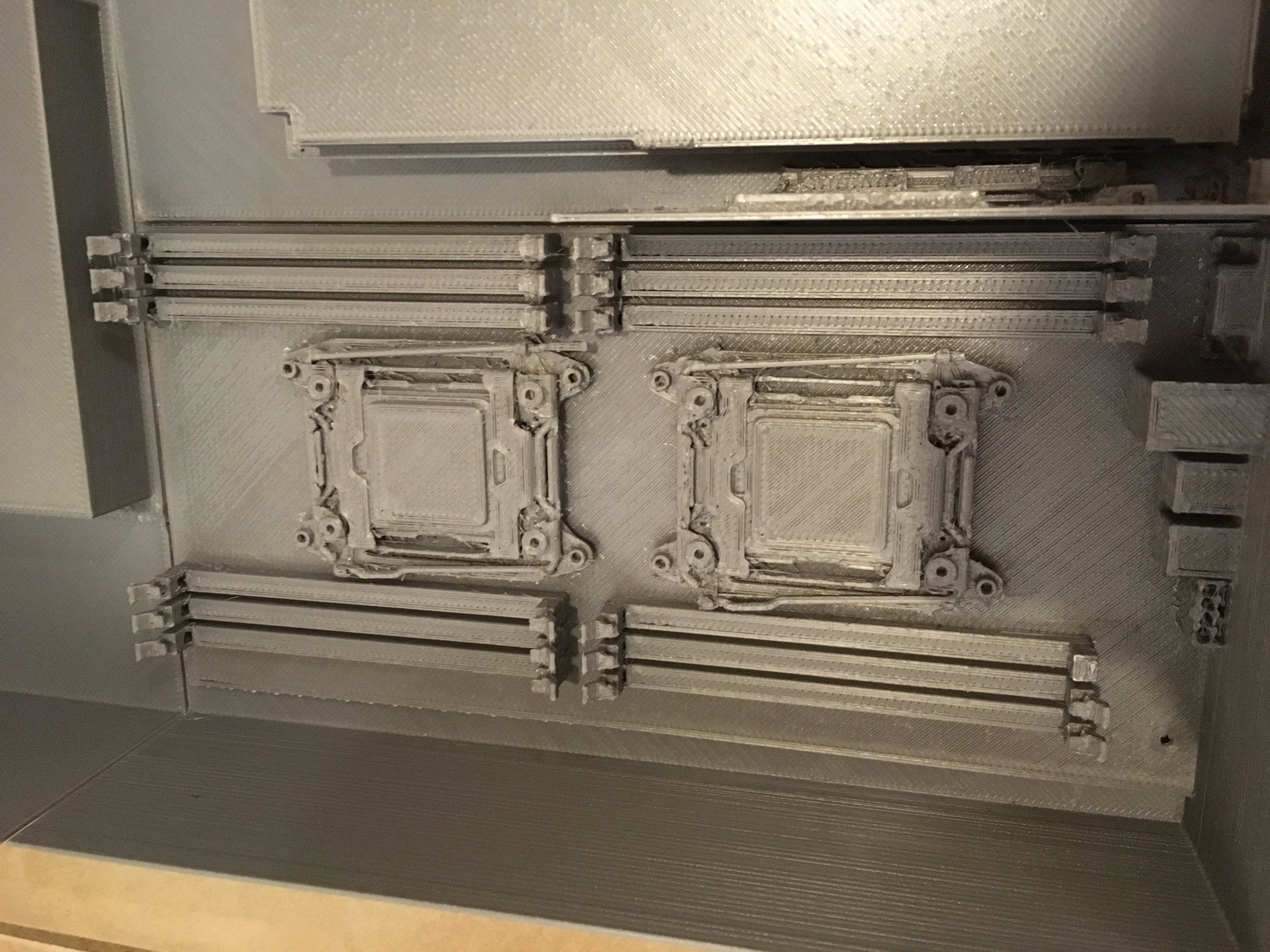

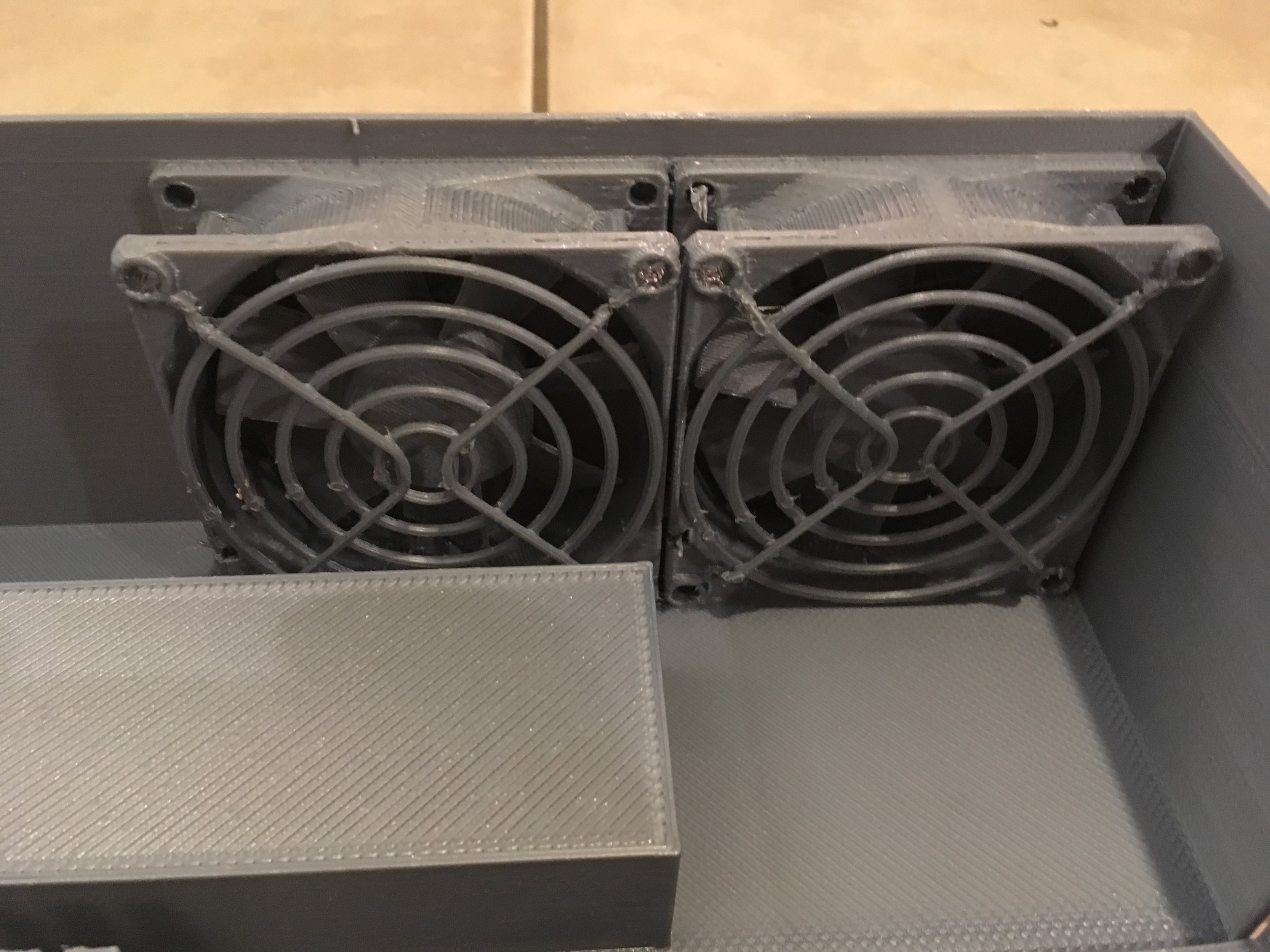

This was no small prototype, either--it was a full-sized computer case demonstrating a new PCI card design. Because of the size of the model, printing it on our largest machine would have taken at least 50 hours even with a large 0.8mm nozzle, which was going to be a problem for making the deadline. We were going to need to get the print done faster to make Scott’s customer meeting a success.

Solution

We were able to come up with a simple solution to enable us to complete the 3D printing more quickly. By splitting the model into 5 pieces and printing it on 3 printers at the same time, we could greatly reduce the time needed to print the entire model. We used Autodesk Meshmixer to split the parts and had our printers running the parts soon after.

With multiple machines on the task, we were able to complete the order much faster than the original 50-hour estimate. Splitting the parts greatly reduced the print time--the longest print only took 18 hours. As the parts were printing, we regularly communicated with Scott to give him updates on the order, including pictures of the completed parts so he was able to verify that the prototype was coming out the way he expected.

We ended up hearing from Scott that it would be best to ship the model in three separate pieces to make it easier to demonstrate the prototype for the customer, so what started as a way for us to complete the printing on time turned into an added benefit for the final product. After printing all of the parts and packaging them securely, we shipped them out on Thursday morning. With overnight shipping, they arrived to Scott on Friday, the morning before his customer meeting.

Although not all of our orders have this tight of a deadline, we see rapid turnaround time as one of the biggest benefits of 3D printing. We specialize in this type of printing and pride ourselves on being able to uniquely handle these types of orders. In this case, our availability at late hours of the day enabled us to start on Scott’s prints as soon as he realized he needed a prototype, which made the difference in allowing him to demonstrate the prototype to his customer.