Optimizing Strength of 3D Printed Parts

Whether you are considering 3D printing for prototypes or end use applications, there are many factors you’ll need to consider to ensure the parts are strong enough for your application. In this article, we’ll take a look at the choices which have the greatest impact on part strength:

- 3D printer settings

- Material choice

- Orientation of the part

3D Printer Settings

Infill Density

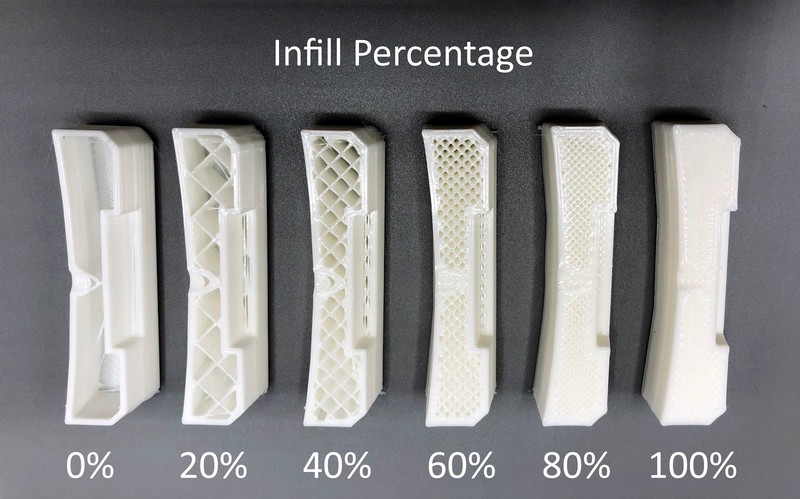

When ordering 3D printed parts, you will typically need to specify an infill percentage. Infill Density represents how dense the interior of the model will be. This setting ranges from 0%, a totally hollow model, to 100%, a totally solid model. Infill has the greatest impact of compression strength, since it acts to support the interior of the model.

It seems obvious that a totally solid model would be the best choice for strength, but in practice, choosing a value beyond 60-70% has very little impact on part strength and is usually not worth the additional cost and print time. Especially for larger models with large internal spaces, increasing the infill can have a drastic impact on both the cost and print time. It is important to consider whether the benefits outweigh the drawbacks for your application.

Increasing the infill percentage improves the strength of 3D printed parts, especially impact resistance, but the benefits taper beyond 60%.

Refer to our Infill Percentage Guide for more details and other considerations for this setting.

Wall Thickness

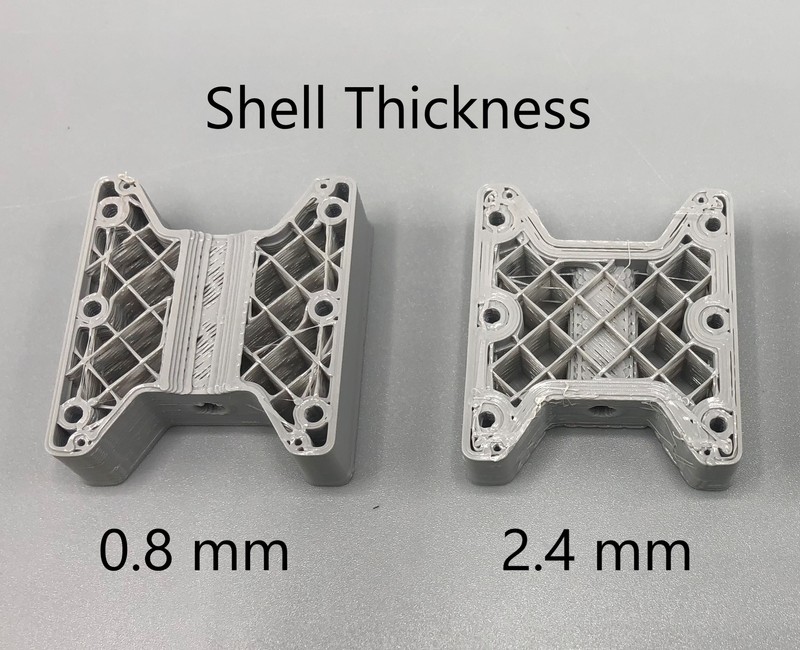

Another lesser known setting, the shell thickness, also plays a significant role in part strength. Wall Thickness refers to the thickness of the outer surfaces of the part. Most 3D printing services use a standard thickness of about 1.0 - 1.5 mm, but increasing this setting can greatly increase the tensile strength and impact strength of your parts.

Increasing the shell thickness of parts can significantly improve the strength of 3D printed parts, even with a lower infill percentage.

Material Choice

The material your parts are made from also has a significant impact on strength. Typically, 3D printed parts are made from PLA, ABS, or PETG plastics. Its important to consider the types of force that your parts will undergo when deciding on the most suitable material.

ABS, PETG, and PLA have differing strength characteristics which are important to consider when 3D printing end use parts.

For parts which need tensile strength to resist forces pulling on the object, PETG is the strongest option, followed by PLA. ABS is the least effective choice for resisting this type of force. PETG has especially strong bonding between layers and is stronger than other options, which is why it is an especially good choice for thin parts with high strength requirements.

If your parts are subjected to bending forces, ABS is typically the strongest option due to its ductility, followed by PETG. PLA is more rigid and brittle than the other options, which means it is not a good choice for applications that require flexural resistance.

If parts need to resist impact, such as being subjected to falls, ABS or PETG perform about equally. PLA is less suitable for this use due to its rigidity.

For more information on material options and other considerations, refer to our Materials Guide.

Part Orientation

Part Orientation, or how the part is positioned on the 3D printer, is a strength consideration unique to 3D printing. As you may know, 3D printed parts are formed by producing stacked layers of extruded plastic.

Althought the plastic of each layer bonds to the previous layer, the interfaces between these layers are a weak point. When 3D Printed parts crack or break, it is typically between layer lines.

Considering this characteristic of 3D printed parts is especially useful when forces are subjected on the part in a specific direction. For example, if you were designing a bracket for a shelf, you know that the largest forces will be pushing downward where the bracket attaches to the shelf. Using this information, printing the bracket on its side will ensure that the force is not acting along the interfaces between layers.

In cases where you cannot avoid forces acting across layers, consider using PETG since it has the best layer bonding performance of the common materials.

Keep in mind that other factors can also impact the best choice for part orientation. For example, part orientation affects which surfaces of the print will be smoothest. In some cases, part orientation can also affect the cost of the print because more support material may be required to enable a certain part orientation.

Other Considerations

While you can use the techniques in this guide to improve the strength of your parts, strength is just one of many factors you are likely thinking about when considering 3D printing for your project. Other requirements, such as the appearance of the parts, cost of production, and timeframe, can require you to make difficult trade-offs. Fortunately, 3D printing allows you to quickly try various options and test the results, so you can get your own sense of how to best optimize these settings.